Product details

1.HIGH PERFORMANCE AND EFFICIENCY

2.Different product lines, modular design and complete specifications with multiple types of automatic changing heads and vertical/horizontal tool changers. Full automation, high efficiency and high productivity can be achieved.

3.The X and Y-axis use high-rigidity roller-type linear slide rails and the axial system can bear heavy load and move fast.

4.The key contact surfaces are carefully hand-scraped to ensure the ultimate accuracy and load balance.

5.All the structural parts have been analyzed by using FEM method and they are featured by lightweight and reasonable design to ensure the optimal structural rigidity of the whole machine.

6.Modular spindle design can be coupled with gear spindle or direct drive spindle to meet the machining requirements of precision molds or parts.

7.Widely used in automobile, aerospace, shipbuilding, power generation, rail transportation, mold and machinery industries, and sold well at home and abroad.

8.Strict parts assembly and inspection process, advanced inspection instruments and precision assembly ensure that each machine has the best working accuracy.

ROTATABLE CONTROL BOX:

The control panel of the pedestal-type rotatable control box and the liftable handwheel operation box are very convenient for the operator to operate in any position and the foot switch can be used to easily clamp or release the tool on the spindle head.

Table bearing: 6000kg,

table size: 1600 × 2500mm

triaxial stroke: 2700 × 1800 × 1000mm

spindle speed: 6000rpm

knife storage capacity: 24pcs.

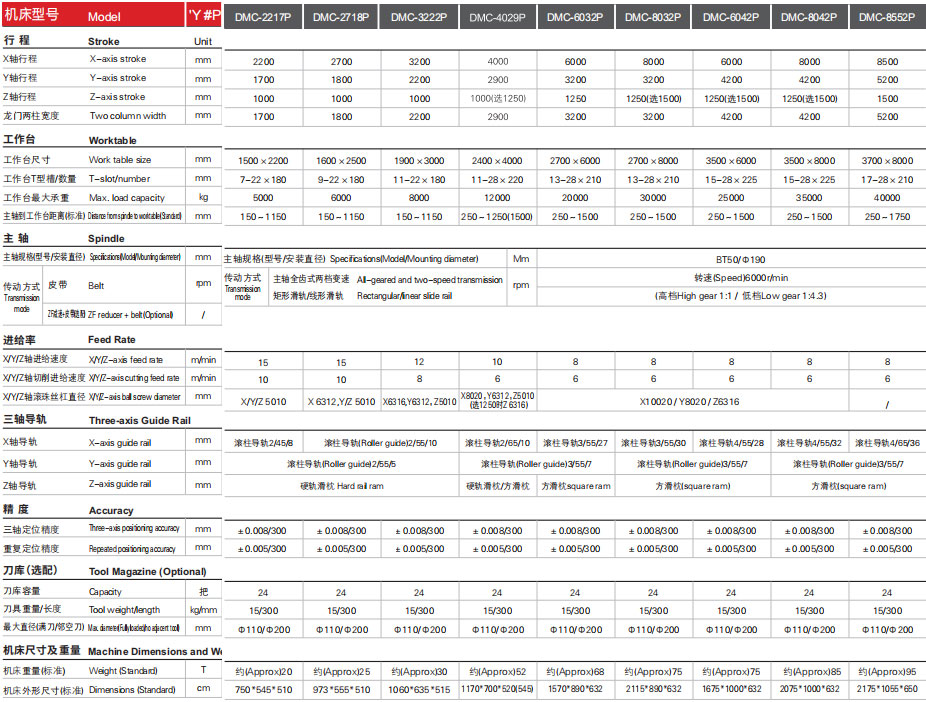

PARAMETERS OF HIGH-PERFORMANCE GANTRY MACHIN ING CENTER

STANDARD CONFIGURATION

| FANUC 0i-MF controller | Belt spindle 6,000rpm | Column side protection (6m machine or above) | Centralized automatic lubrication system |

| Mobile hand wheel (MPG) | Power transformer (380V-220V) | Topless perimeter protection (4m machine or below) | Cooling system (Including pump and water tank) |

| Work light and warning light | Horizontal suspended operator box | Twin-screw chip roller and chain plate iron chip conveyor | Independent lubricant recovery system |

| RS-232 / RJ45 / USB interface | Water gun and air gun | Foundation bolts and horizontal adjustment tool (1 set) | Spindle temperature control system (Oil cooler) |

| Auto power-off function | Technical document (1 set) | Foot-operated tool release switch | Double hydraulic cylinder counterweight sy |