SERVO TURRET

1.Driven by servo motor with high positioning accuracy, rapid movement, excellent stability and without disorderly cutting.

2.Fast speed 90rpm,1.2sec/rev and 0.8sec for adjacent tool (12 tools). VDI tool disk or angle tool disk can be provided according to customer requirements.

NEWLY UPGRADED FULL RANGE OF PRODUCTS

1.Suitable for machining shaft parts, threads, arcs, cones and internal/external surfaces of rotating parts.

2.Especially suitable for efficient, high-volume and high-precision machining of rotating parts in automobile, electronic, motorcycle, home appliance, furniture and lighting decoration industries.

3.Slant-bed CNC lathe can tilt 30°, which enhances the chip removal ability and saves the footprint.

WORKPIECE SHOWCASE

|  |

HIGH PERFORMANCE ACCESSORIES

The machine tool is fully enclosed to ensure the personal safety in the machining process and the coolant and iron chips can be safely and completely recycled to ensure the cleanliness of the workplace.

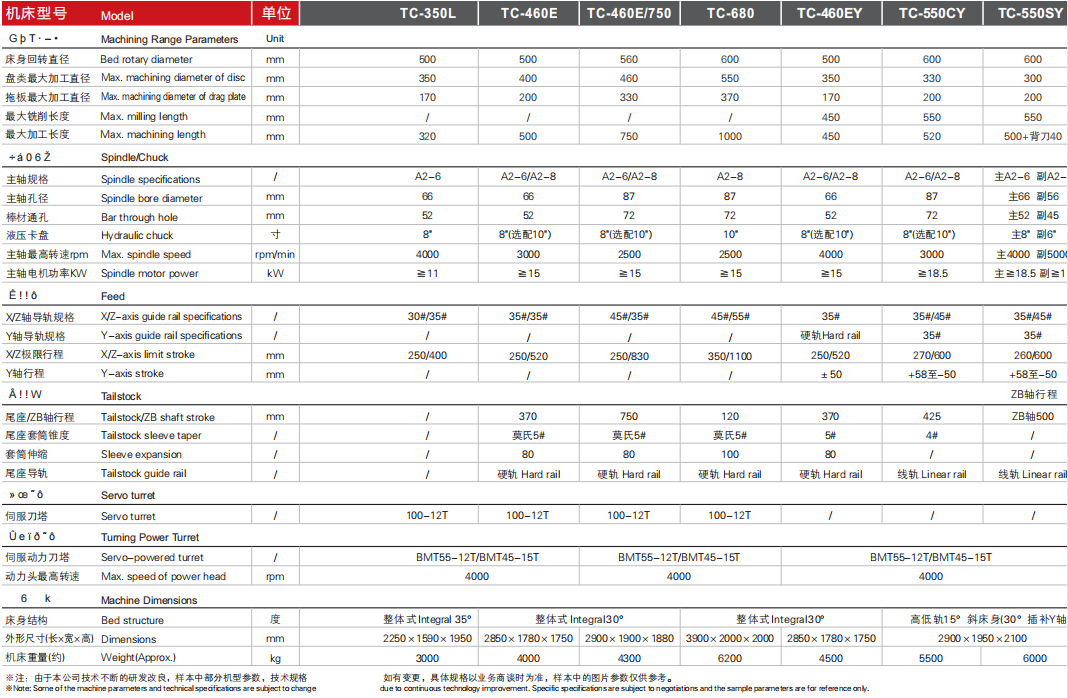

Lathe series technical parameters

STANDARD CONFIGURATION

| Taiwan SYNTEC 22TB CNC system | Fully enclosed cover | Chip box |

| Hydraulic turret (12-station servo turret) | Automatic lubrication system | Foot switch |

| 8” Hollow hydraulic chuck | Adjusting iron gasket | Hydraulic tailstock |

| Cooling system | Servo motor | Three-color indicator |

OPTIONAL PARTS

Fanuc and MITSUBISHI systems

Automatic chip remover(Including chip collector)

10" Hydraulic power chuck