Product details

1.Win the reputation of customers with heavy cutting resistance, stability and precision. Apart from excellent design and construction, we also use various precision instruments to ensure the product quality.

2.The Z-axis adopts the large T-shaped hard rail, which has good vibration absorption and wear-resistant performance. Traditional scraping technique is also used to ensure the accuracy for a long time.

3.The new design of the rigid structure shows better accessibility and effective water and chip resistance. A wide range of accessory heads and a variety of head changers are available to meet different processing requirements.

FULL TOOTH TWO SPEED TRANSMISSION GEARBOX

1.Cooperating with a full tooth two speed gearbox (high gear 1:1/low gear 1:4.3), it is directly transmitted through gears, ensuring smooth transmission and high efficiency (over 95%). The shifting of the full tooth gearbox is controlled by hydraulic pressure, ensuring stable and reliable shifting.

2.Due to the use of a full tooth two-stage gearbox for the main transmission, the low speed torque of the main shaft is significantly increased (about 4.3 times), thereby improving the processing efficiency of users when using larger diameter cutting tools.

Table bearing: 20000kg

table size: 2700 × 6000mm

triaxial stroke: 6000 × 3200 × 1250mm

spindle speed: 6000rpm

knife storage capacity: 24pcs

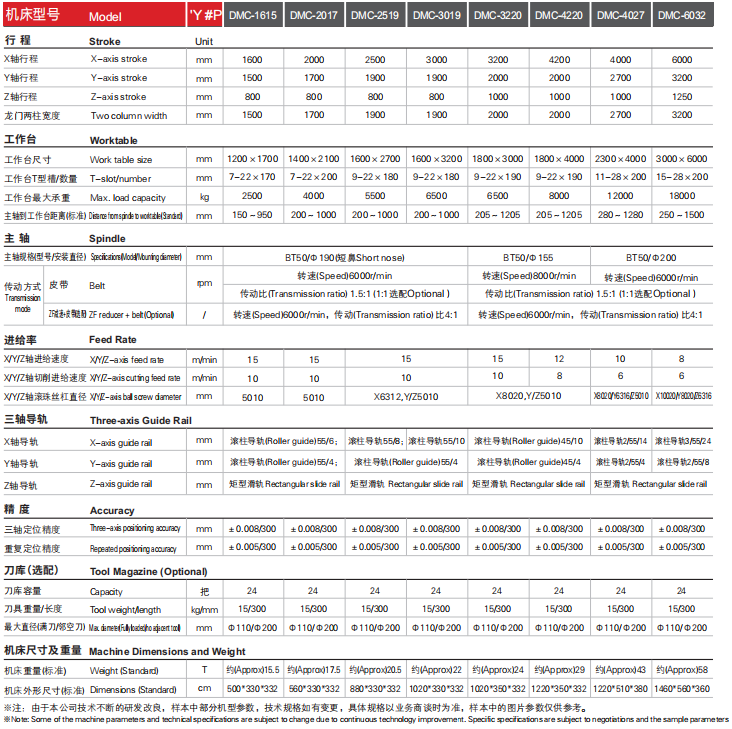

PARAMETERS OF HIGH-PERFORMANCE GANTRY MACHIN ING CENTER

STANDARD CONFIGURATION

| FANUC 0i-MF controller | Belt spindle 6,000rpm | Column side protection (6m machine or above) | Centralized automatic lubrication system |

| Mobile hand wheel (MPG) | Power transformer (380V-220V) | Topless perimeter protection (4m machine or below) | Cooling system (Including pump and water tank) |

| Work light and warning light | Horizontal suspended operator box | Twin-screw chip roller and chain plate iron chip conveyor | Independent lubricant recovery system |

| RS-232 / RJ45 / USB interface | Water gun and air gun | Foundation bolts and horizontal adjustment tool (1 set) | Spindle temperature control system (Oil cooler) |

| Auto power-off function | Technical document (1 set) | Foot-operated tool release switch | Double hydraulic cylinder counterweight sy |