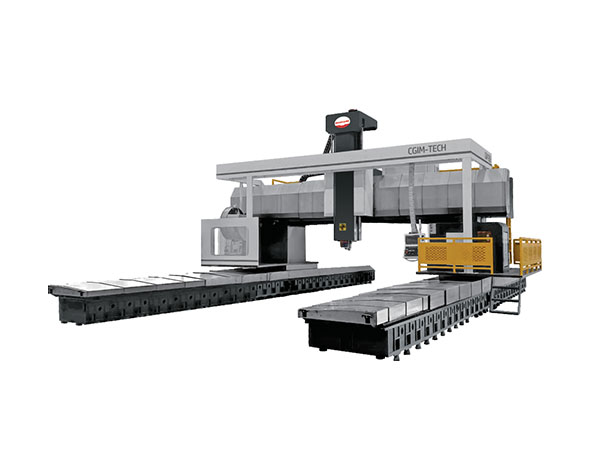

Product details

1.With the high rigidity and heavy cutting structure design, the whole series of machines have high precision of five-sided machining centers and all-round high-efficiency cutting is achieved with robust structure and superior geometrical precision.

2.Full-automatic five-sided machining capability and full-automatic additional head change.

3.The X and Y-axis use high rigidity and high precision linear slide rails. X-axis is supported by four symmetrical rails.

4.The Z-axis is designed with high rigidity hard rail, heat-treated and then precision ground, suitable for heavy cutting.

5.All structural parts are analyzed by using finite element method (FEM). They are featured by lightweight and reasonable design to ensure the optimal structural rigidity of the whole machine.

THREE-AXIS RAIL DESIGN: LINEAR RAIL LINEAR RAIL/HARD RAIL

The X and Y-axis use double-loaded roller-type linear rails with track width of 55mm. The Z-axis uses hard rails with good vibration absorption and wear resistance.

STRUCTURAL CHARACTERISTICS OF CROSS RAIL COLUMN

The cross rail is cast as one piece with high rigidity cross ribs at the front and box structure at the rear. They are evenly distributed at the rear cross rail. The bridge type arch design can effectively support the vertical gravity and lateral resistance for stable cutting.

SPINDLE GEARBOX

The spindle head adopts quadrilateral high rigidity design with square structure and 500×500rm. It has enough strength and not easy to interfere with the machined workpiece. The slide rail has the ladder-type cladding design and the spindle center is closer to the cross rail with stable cutting capability. The gear box and spindle are machined as one piece, which has a short transmission distance for cutting torque, strong output force, stable cutting resistance and low noise for long time operation.

Table bearing: 5ton/cm

table size: 16,000 × 5,000 mm

triaxial stroke: 16,000 × 6,500 × 1,500 mm

spindle speed: 6,000 rpm

knife storage capacity: 24 pcs

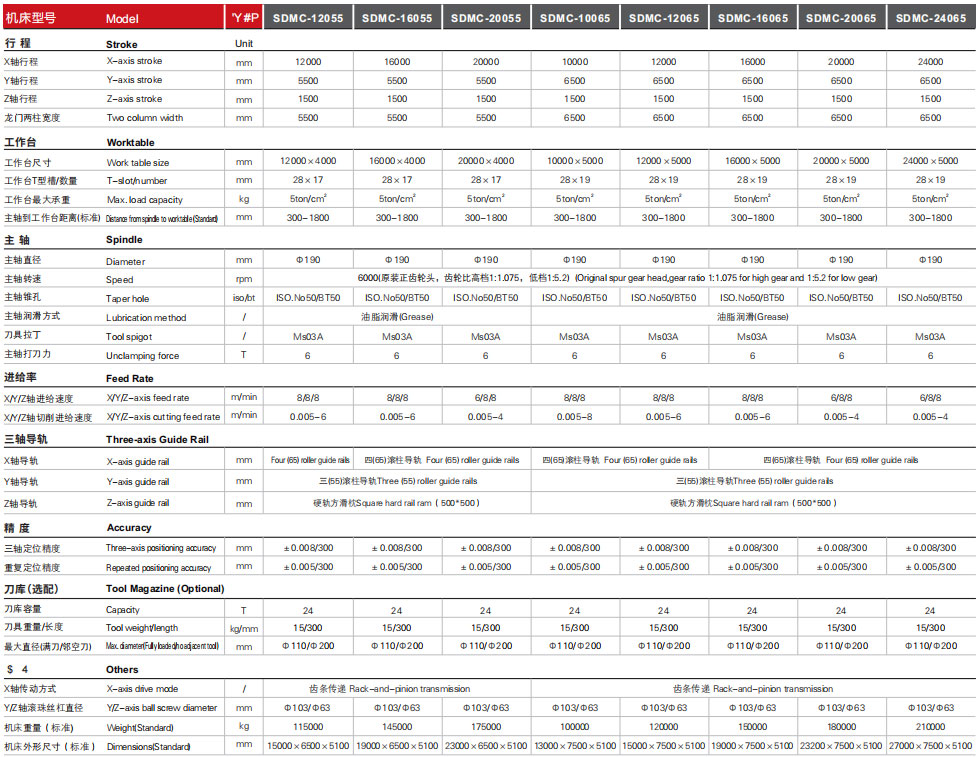

PARAMETERS OF MOVABLE COLUMN GANTRY MACHINING CENTER

STANDARD CONFIGURATION

| FANUC 0i-MF controller | Gear transmission spindle 6,000rpm | Column side protection (6m machine or above | Centralized automatic lubrication system |

| Mobile hand wheel (MPG) | Power transformer (380V-220V) | Topless perimeter protection (4m machine or below) | Cooling system (Including pump and water |

| Work light and warning light | Horizontal suspended operator box | Twin-screw chip roller and chain plate iron chip conveyor | Independent lubricant recovery system |

| RS-232 / RJ45 / USB interface | Water gun and air gun | Foundation bolts and horizontal adjustment tool (1 set) | Spindle temperature control system (Oil cooler) |

| Auto power-off function | Technical document (1 set) | Foot-operated tool release switch | Double hydraulic cylinder counterweight sy |