Product details

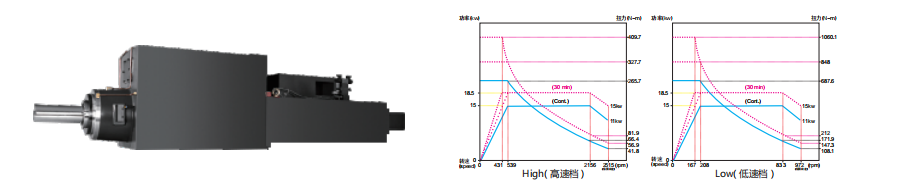

1.High torque spindle design: The spindle is made of chrome molybdenum steel with hardness up to HRC60-62, which ensures the best rigidity and precision. The boring bar can be extended to 500/800/1000 long with the capability of deep hole machining and the true roundness is micron level.

2.High-precision turntable: The turntable (B-axis) is hydraulically clamped and the accuracy retention is excellent during heavy cutting. It is servo controlled and automatically positioned, which meets different machining requirements and its disk is professionally scraped.

High Torque Spindle Design

The spindle is made of chrome-molybdenum steel with the hardness of HRC60-62 to ensure the best rigidity and precision. The boring bar can be extended to 800mm long, which has the capability of deep hole machining and the true roundness is U level.

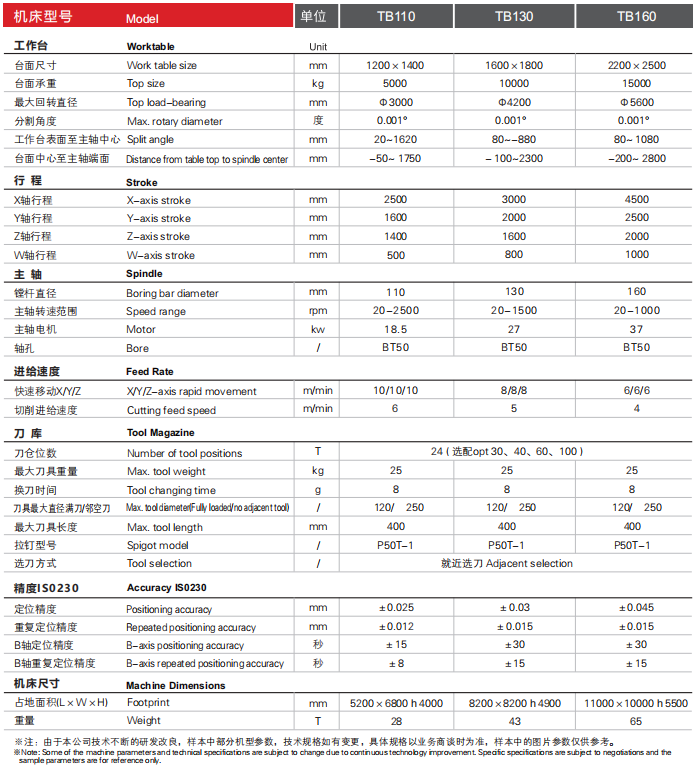

PARAMETERS OF CNC HORIZONTAL BORING AND MILLING CENTER