Product details

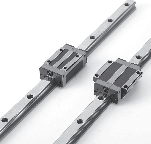

1.All three axes use high rigidity roller linear guide rails with good bearing capacity, high transmission precision and excellent precision retention. It can meet the requirements of rough machining and fine machining.

2.High precision and high rigidity spindle head can bear radial and axial heavy cutting and long-time cutting. It can also maintain a high degree of machining accuracy.

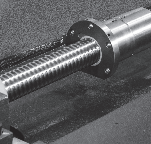

3.All three axes use high-precision precision ball screws with double nut preload, together with the locking and pulling design of the support base at both ends. It can eliminate the backlash in transmission and pre-compensate for the error caused by temperature rise to ensure the positioning accuracy.

Three-Axis Standard Roller Linear Rail

High load bearing capacity and strong cutting resistance to vibration;Low friction at high speed, responsive acceleration and high positioning accuracy.

Spindle Cooling System

The spindle head has a built-in independent cooling system to control the spindle head temperature in a reasonable range and reduce the thermal extension.

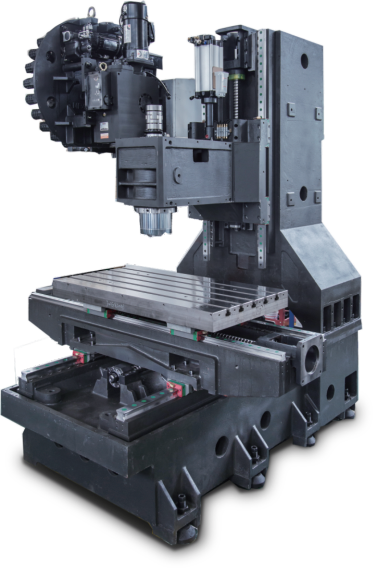

MACHINE TOOL FEATURES

Reinforced Structural Parts

The column castings are made of high-grade resin sand. The column span is large and the installation is secure. The internal reinforcing ribs are reasonably structured, which can easily meet the machining requirements of different industries.

Significantly Improved Vibration Damping Performance

The base castings are made of high-grade resin sand. After demolding, they are subjected to artificial aging treatment and vibration aging treatment to eliminate internal stresses and maintain excellent precision retention. Cross-shaped reinforcing ribs are used internally with reasonable layout.

|

|

ANNULAR SPRAY DEVICE

The spindle can be equipped with an optional annular spray device, which helps to cool the tool during drilling and tapping, and also helps in chip removal.

|

|

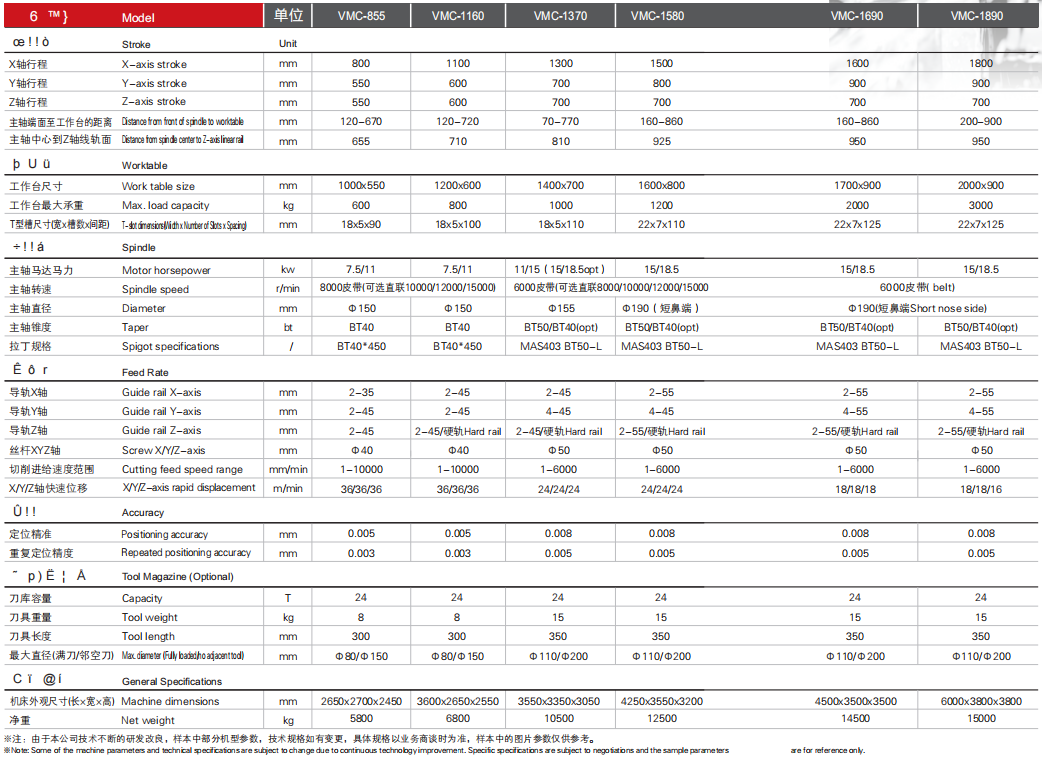

Technical parameters of vertical machining center

Standard Configuration

Mitsubishi or FANUC control system,Electrical box heat exchanger,Ethernet、LED work light,Mobile handwheel、Fully enclosed cover,Automatic lubrication system,Rigid tapping device,24T Disc tool magazine,Spindle oil cooler、Cutting fluid system,Retractable chute steel cover,Cutting fluid tank and filter,Adjusting screw and washer,Working status indicator,Isolated transformer,Operating manual、Toolbox ,Shadowless lighting device

Optional Parts

Fourth axis、Gearbox,Automatic tool length measuring instrument,BBT40/HSK63A ,Cradle type 5-axis,Crawler-type chip remover with chip collector ,Automatic safety door,Oil-water separator,Three-axis optical ruler,Spindle center outlet ,Side milling head (Manual device),High pressure chip flushing device

|  |  |  |  |